| Perfimur flashing cover |

|

| Description |

|

| PERFIMUR cover panels are manufactured through a continuous manufacturing process using the most modern technologies. The sandwich panel is formed by an outlined metallic face wall, inside which a core of polyurethane foam works as a thermal insulating. This provides it with a great solidity thanks to the excellent adherence of polyurethane to metallic parameters, due to the special treatment that steel sheet received. |

|

|

| This panel fastening is made through screws hidden by the flashing, created for such purposes. Besides, this flashing guarantees full water-resistance because it avoids the entrance of water, even by capillarity. |

|

|

|

| Steel |

|

| PERFIMUR uses high-quality pre-lacquered steels. Steel galvanised sheet Z225 by zinc immersion (Sendzimir process) SIN EN 1 0142 and DX51D quality of 0.6 mm thickness and pre-lacquering covering depending on needs (polyester, Plastisol, PVDF, etc.). It is also possible to use other sheet thickness following a previous study. |

|

| Application |

|

| Minimum roof pitch of 5% for covers without flap. Minimum 7% for covers with flap. |

|

| Panel basic data |

|

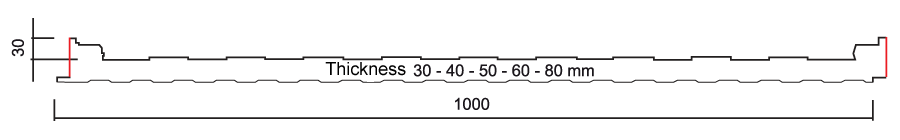

| Useful width |

1.000 mm |

| Maximum length |

15.000 mm |

| Polyurethane density |

40 Kg/m3 |

| Nominal thickness |

30 - 40 - 50 - 60 - 80 mm |

| Maximum thickness in crests |

33 mm |

|

|

|

|

| Panels weight |

|

|

| Panel thickness (mm) |

30 |

40 |

50 |

60 |

80 |

| Weight (Kg/m2) |

9,55 |

9,95 |

10,35 |

10,75 |

11,55 |

|

|

| Thermal properties |

|

|

| Thickness (mm) |

K (Kcal/m2 x h x C) |

K (W/m2 x C) |

| 30 |

0,52 |

0,60 |

| 40 |

0,41 |

0,48 |

| 50 |

0,34 |

0,40 |

| 60 |

0,29 |

0,34 |

| 80 |

0,23 |

0,27 |

|

|

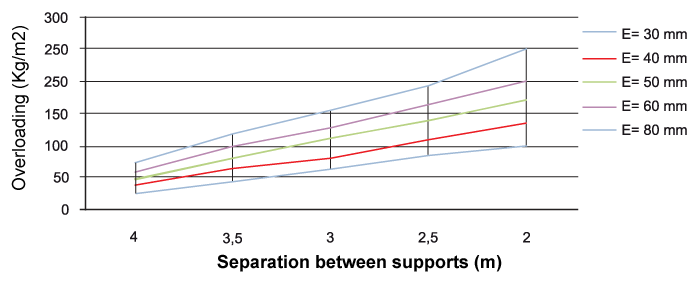

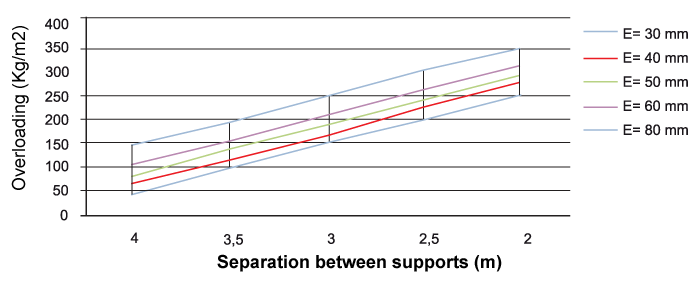

| Mechanical properties |

|

| 2 supports |

|

|

| 3 supports |

|

|

|

|

| Perfiles Murcia S.A. reserves the right to change the characteristics when needed for its improvement. The data presented are not warranty conditions, due to the existent resistance in raw materials. |

|

|